Hello! As soon as I bought my plot, I immediately started building a greenhouse.

The problem was quickly solved and then for a long time I enjoyed the taste of fresh vegetables. Until last season arrived. I don’t know for what reason, but the greenhouse was attacked by several types of pests.

I decided on drastic measures: I used a sulfur checker for a polycarbonate greenhouse. We managed to get rid of pests. I want to tell you now about all the nuances of using such a tool, how to achieve maximum effect. Enjoy reading.

The content of the article:

Sulfuric checker for a polycarbonate greenhouse - types of how to use

Indoor plants are susceptible to many diseases and pests. Avoid this will help the annual disinfection of the greenhouse with the help of sulfur blocks. This method of disinfection allows you to get rid of diseases and insects in one or two procedures.

The technology for fumigating greenhouses with smoke bombs is quite simple, but in order to be effective and safe, you must strictly follow the instructions.

Operating principle

Sulfur block is a set of tablets containing the active substance - sulfur - in an amount of 750 g / kg. When smoldering, the checker releases sulphurous anhydride, which effectively kills bacteria, viruses and fungi, as well as harmful insects. On rodents, the checker acts depressingly and scares them away.

For processing, take the right amount of tablets, set fire to them with a wick and leave the smolder block in a tightly closed greenhouse. In this case, a large volume of smoke is formed, which fills the structure.

Smoke easily penetrates into inaccessible places: joints of frame elements, polycarbonate, crevices in the foundation and barriers of beds - where pests and pathogens accumulate.

When combined with vapors and drops of moisture, the anhydride forms sulfuric acid, which gives an additional disinfecting effect, disinfects the soil and walls of the greenhouse.

When to process

Disinfection of the greenhouse using checkers is carried out in the fall, after the end of the growing season and the full cleaning of the greenhouse, as well as in the spring, not later than two weeks before the first crops are planted. Autumn processing is usually carried out in September or early October. In spring, you can start disinfection in April.

Otherwise, sulfuric acid will penetrate into the deep layers of the soil, which will adversely affect the activity of soil bacteria.

The benefits and harms of sulfur drafts

Before proceeding with the treatment of the greenhouse with a sulfur block, it is necessary to evaluate its benefits and harms for the structure itself, soil and plants.

Advantages of sulfur drafts:

- effective against fungus and mold, bacteria and harmful insects;

- has high penetration;

- economical;

- easy to use.

But there are also disadvantages that should also be remembered.

The toxicity of sulfur drafts is extremely high, therefore its use requires compliance with safety rules. Sulfur smoke bombs are very toxic!

- Sulfur anhydride has a destructive effect on unprotected metal parts of the frame.

- Polycarbonate, after repeated treatments, becomes cloudy and becomes microcracked.

- Acid resulting from the reaction of smoke with water kills not only harmful, but also beneficial microorganisms, impairing soil fertility.

- The action of the sulfur block does not apply to the deep layers of the soil.

- Processing can not be carried out during the growing season and less than two weeks before planting.

When using sulfur drafts, the safety precautions must be strictly observed: the drafts are fire hazardous, and its smoke is poisonous!

Given all the shortcomings and difficulties in using sulfur drafts, before its use it is necessary to evaluate the appropriateness of processing. Experienced gardeners are advised to use a sulfur checker in the following cases.

- For several years in a greenhouse plants of the same species, having common pests and diseases, were grown.

- During the season, outbreaks of fungal and bacterial diseases with a large lesion area were observed in the greenhouse or in the immediate vicinity of it.

- Pests were observed on plants, and the fight against them using folk remedies or systemic insecticides was ineffective.

- Plants in the greenhouse are infected with a spider mite - it is poorly excreted by conventional means.

In other cases, prophylactic disinfection of greenhouses is best carried out using biological products - they do not have a harmful effect on the soil and the design of the greenhouse. You can also use other types of checkers with fungicidal and insecticidal action.

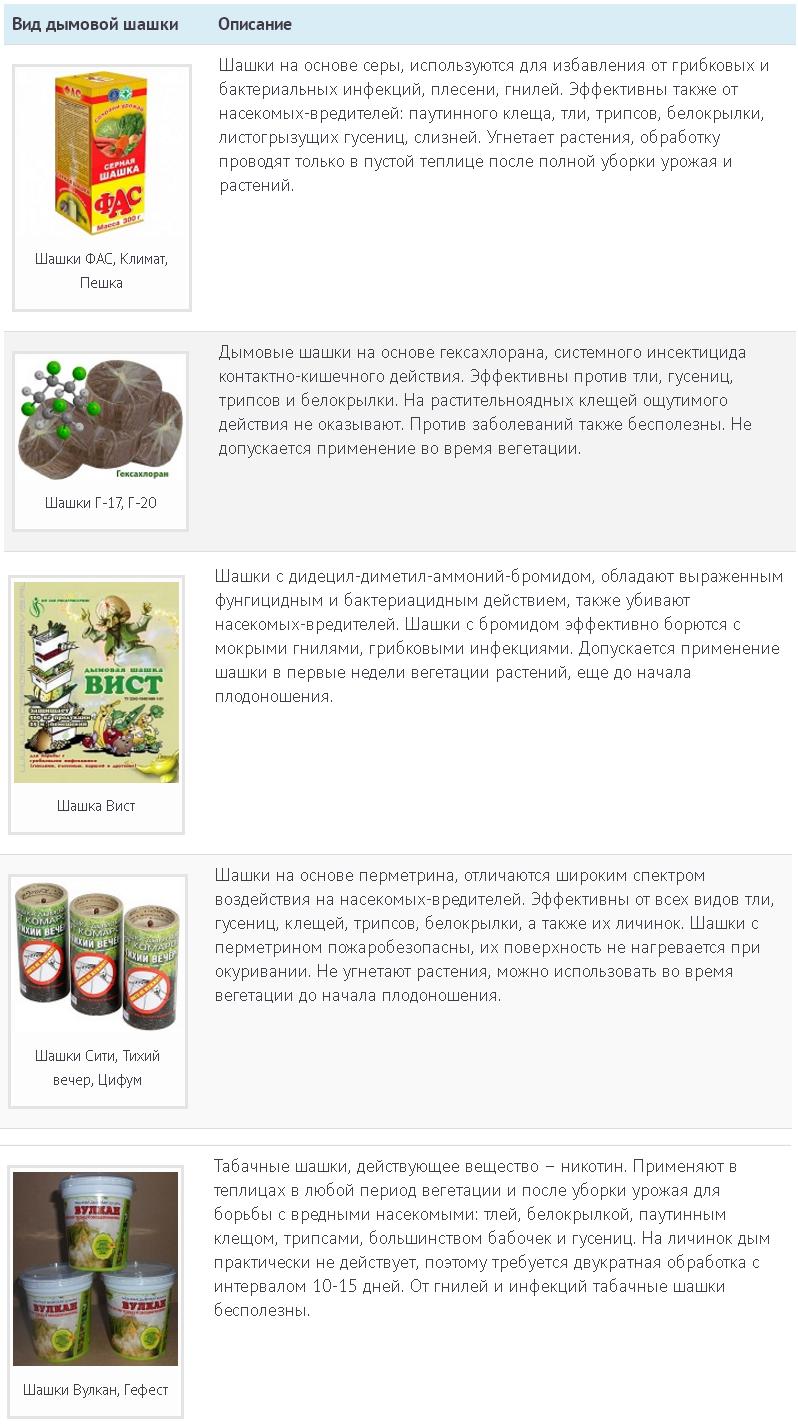

Types of smoke bombs

Which sulfur block to choose for processing a polycarbonate greenhouse? This question excites many beginning summer residents.

Often, sulfuric drafts are mistakenly classified as means for the destruction of insects and microorganisms based on other toxic substances. The scope of the smoke bomb and its effectiveness depend on the active substance.

As can be seen from the table, sulfur checkers have the widest spectrum of action, so they are most often chosen for the complete disinfection of greenhouses after the end of the season. In order not to harm the soil, the frame of the greenhouse and polycarbonate, it is necessary to observe the processing technology.

Greenhouse Processing Technology

The process of fumigating a greenhouse with a sulfur checker does not take much time - the checker burns for several hours. However, the action of sulfur dioxide lasts for two to three days. To increase the effectiveness of the drug, it is recommended to choose the right dosage and follow the step-by-step processing instructions.

Dosage calculation

A checker consists of several tablets, which allows you to most accurately select the dose of the active substance. The calculation is carried out according to the volume of the greenhouse, the consumption of the active substance is indicated on the package.

The following is an example calculation:

- For processing the greenhouse, a Climate checker weighing 300 grams, 10 tablets was selected. The size of the greenhouse is 3x6x2.2 meters.

- The calculation of the volume of the greenhouse is quite simple: it is necessary to multiply its geometric dimensions in meters, as a result, the volume in cubic meters is obtained. For the given dimensions of the greenhouse it will be 3 · 6 · 2.2 = 39.6 m3.

- One piece weighing 300 g according to the manufacturer's recommendations is enough to process 20 m3 of the greenhouse.

- To process the greenhouse, you need 39.6: 20 = 1.98, that is, 2 pieces of 300 g each or 20 tablets.

The estimated number of pieces is divided into several groups so that fumigation is carried out evenly. It should be noted that the wick smoldering time is 90 seconds, after which toxic gas is released.

The number of checkers must be calculated so as to have time to set fire to them and leave the greenhouse in a minute and a half.

With a large volume of the greenhouse and the simultaneous use of several checkers in order to avoid poisoning, it is recommended to use a gas mask and a protective suit.

How to use

Not only processing efficiency, but also your safety depends on the proper use of checkers. Therefore, it is recommended to strictly follow the instructions.

Step-by-step instructions for using sulfuric checkers in a greenhouse:

Harvesting cultivated plants and weeds - Processing the greenhouse with a sulfur block is carried out only after the vegetation has been completely removed from the greenhouse. Cultivated plants are removed, tops and residues are burned. Using them for compost is not recommended.

General cleaning in the greenhouse. The walls of the greenhouse are washed with warm water and a liquid detergent. For washing, I use a soft sponge or rag, the use of brushes and scrapers for polycarbonate is not recommended - you can damage its surface, after which it becomes cloudy.

When washing, special attention is paid to the joints of polycarbonate and the frame. Dust and dirt usually accumulate there, bacteria, fungal spores and ticks hibernate in them. They can be additionally cleaned with a soft brush. Finally, the walls of the greenhouse are washed with water from a hose.

Tillage. Smoke from a sulfuric bomb can penetrate only into loose soil to a depth of not more than 5 cm. Most pests larvae hibernate for greater depths.

Greenhouse Sealing. The use of sulfur checkers is possible only in an airtight room, otherwise the smoke will come out and the checker will be ineffective. In addition, the smoke is toxic, poisoning can be produced when it is released. The greenhouse is sealed by sealing cracks and joints with sealant, adhesive tape or putty.

To enter the greenhouse, one of the doors is left, while it can be sealed with a rubber sealant for windows, and after firing up the checkers, it is additionally sealed with tape.

Protection for metal structures. When exposed to sulfur dioxide on unprotected metal, a corrosion center is formed. Therefore, checkers manufacturers recommend that before starting processing, coat unpainted metal parts with solid oil or other organic grease.

Particular attention should be paid to parts experiencing mechanical stress: door hinges, door frames and window leaves - there the paint leaves most often.

Personal Security

Smoke from the checker is toxic, and if it gets on wet skin, it can cause irritation.Therefore, before starting treatment it is necessary to wear protective clothing - a special suit or overalls made of thick fabric with long sleeves. They put gloves on their hands, protect their heads with a hood or scarf. Respiratory protection with a respirator. If possible, use a gas mask.

Wetting surfaces. To increase efficiency, immediately before processing, moisten the walls of the greenhouse and the topsoil from a hose or sprayer. High humidity promotes the conversion of sulphurous anhydride to sulphurous acid, which is an antiseptic and preservative.

Upon contact with moisture, ash or some mineral fertilizers, sulfuric acid turns into sulfuric acid, the effect of which on the soil is extremely negative, so you can not fertilize the soil in the greenhouse before processing with a checker!

Preparation of the base for the checker. Sulfur checker is heated during smoldering, for its use it is necessary to prepare a non-combustible base. It can be paving slabs, a sheet of metal, an enameled basin or a bucket.

If there are concrete or tile tracks in the greenhouse, you can put a checker directly on them, provided that there are no combustible objects nearby.

Checkers ignition The checker is installed on the base strictly vertically, a wick is included under the top tablet, which is included with the checker. In its absence, the saber is fired with the help of a newspaper.

Greenhouse fumigation and disinfection. Smoke emission continues for several hours. It completely fills the greenhouse, settles on the walls, soil and in inaccessible places. The effect of anhydride on bacteria and pests lasts for 24-72 hours, so in the next three days it is better not to open the greenhouse.

Airing and subsequent cleaning. After holding for three days in a greenhouse, doors and windows are opened and aerated until a specific smell disappears. To avoid clouding of polycarbonate and frame corrosion, it is recommended to rinse the greenhouse with a small amount of clean water.

Subsequent soil treatment with EM preparations. Sulfur checker has a negative effect on soil microorganisms, kills beneficial fungi and bacteria. To restore soil fertility, it is recommended to introduce a solution of biological products, such as Emochka, Baikal EM1, Radiance EM2, before the start of the new season.

Processing must begin with the harvesting of all plant debris, weeds, mulch - various pests can hide and winter in them. The tops affected by diseases and pests are burned.

To protect against bacterial and fungal infections, one treatment of the greenhouse with a sulfur block is enough. To eliminate the spider mite, two to three fumigation may be required at weekly intervals.

You can combine a sulfur checker with other methods of disinfection of the greenhouse, which will guarantee to get rid of diseases and pests.

Sulfuric checker for processing polycarbonate greenhouse

Sulfur checker for a polycarbonate greenhouse is a guarantee of a wonderful harvest and the absence of diseases in greenhouse vegetables.

The best option for disinfection of greenhouse buildings is a smoke bomb. This is an affordable and high-quality weapon for the fight against microorganisms and diseases.

Checkers are different

For sanitation of the greenhouse, various checkers are selected depending on the purpose of use. Various components affect the properties of the acquired checkers. If fungi, small insects, bacteria overcome, then it is better to use sulfur drafts.

To eliminate caterpillars and insects living in the soil, the use of hexachloran will be more appropriate, it is effective against coccicides and herbivorous mites.

The best effect in the etching of fungal and bacterial infections and the destruction of all insects will help to achieve didecyldimethylammonium bromide blocks.

Flying insects will disappear due to permethrin. Usually it is used against ants and moths. To counter diseases and insects, tobacco smoke bombs are often used.

The use of sulfur checkers for the purpose of disinfecting a polycarbonate greenhouse is regarded as the most effective method of disinfecting not only the soil, but also the building itself.

The elimination of pests and diseases in this case is accomplished by the method of fumigation. Smoke permeates all inaccessible places of the greenhouse. Using this method, you can achieve the processing of significant areas with the lowest cost and without much difficulty.

If the greenhouse is susceptible to severe infection, it is advisable to repeat the process of fumigation several more times.

Pros and cons of special greenhouse processing

The best brands in the opinion of professionals in the field of growing greenhouse plants are Fas, Hephaestus, and Whist. They eliminate almost all varieties of fungal and bacterial infections, as well as insect larvae.

If the infection was weak, it is best to produce fumigation in the autumn period, be sure after thorough cleaning of the greenhouse.

The use of tobacco checkers during the growth and ripening of vegetables is not prohibited, in this case they do not represent any danger.

The ability to etch various infections and insects, disinfect the soil and cover the greenhouse does not indicate the safety of using this kind of product. Small doses of sulfur are not dangerous, sometimes they are even used in conservation for the long-term preservation of the product.

However, if the concentration is more than acceptable, then serious harm can be done to human health, so do not neglect personal protective equipment in the process of fumigation.

Despite the denial of the possibility of formation of sulfurous acid during smoldering drafts, chemists do not state the opposite. Upon contact of sulfur dioxide with water and ash, the presence of which in the greenhouse is simply necessary, sulfuric acid is formed. It can have a harmful effect on the soil.

The usefulness of sulfuric checkers for the greenhouse is not always an indisputable factor. According to experienced plant growers, the checker should not be put into operation for buildings on a metal base, since the precipitating acid has a corrosive effect on the metal, leading to its gradual destruction. The metal base can be greased with solid oil.

Worry is also the impact of sulfur dioxide on whitewashed surfaces. Sulfur dioxide is not dangerous for greenhouses on a wooden or painted frame. The acid does not affect the frames from profiles with anti-corrosion coating.

Processing Rules

To get the most benefit from the use of checkers, you need to approach very seriously and seriously to the processing itself:

- be sure to make a full cleaning of the room;

- fully equipped with personal protective equipment;

- seal the greenhouse as best as possible;

- moisten all surfaces;

- evenly distribute checkers throughout the greenhouse on non-combustible objects (iron or aluminum sheets, bricks, flat stones can be) to prevent ignition of flammable objects;

- it is possible to set fire to a checker either using a paper sheet or using kerosene (it is strictly forbidden to use gasoline for this purpose);

- go out, closing the door tightly behind him, and leave the saber smoking for 3 days;

- ventilate the greenhouse until the smell of sulfur disappears.

It must be remembered that you cannot be in the greenhouse during smoldering checkers. After completing the process of firing the checkers, you must immediately wash your face and hands, rinse your mouth. Failure to observe safety precautions could result in poisoning. The following symptoms indicate smoke poisoning:

- headache;

- chest pain;

- coughing and hoarseness;

- nosebleeds and sharp pain in the eyes.

Assistance to the victim in this case consists in transferring him to fresh air and contacting a toxicologist. Do not worry about your well-being in the case of the correct use of checkers.

Sulfur treatment cannot be combined with treatment with other disinfectants. When used correctly, the result will be only positive. Plants will always respond to such a departure with an abundance of crops.

Sulfur Checkers for Greenhouses

There are several ways to protect premises and outbuildings (cellars, warehouses, greenhouses) and technological equipment from fungal diseases and mold, from common bacterial rot. One of the most effective is fumigation of sulfuric drafts.

Sulfur smoke was used to get rid of mold since ancient times. Today the specialized sulfur checker PESHA-S, which was created to fight for the preservation of plants and crops, has proved its high efficiency.

It was created taking into account the experience gained over the years of using this substance. The substance that is released during the operation of checkers (sulfur) helps protect plants from common diseases.

So, treating the greenhouse with a sulfur checker will protect your future crop from a whole complex of fungal diseases, effectively relieve powdery mildew, mold and spider mites.

Under the operation of the checker is meant not combustion or decay, but dry sublimation - a process during which a lot of dense smoke and less (compared to burning) sulfuric acid are formed, which is therefore safe for metal structures in rooms.

How to use a checker

Sulfur checker is a case with a wick, which goes to a special pyrotechnic composition. When the wick is ignited, the checker begins to emit thick sulfur smoke - an aerosol.

Sulfur checker is suitable for processing a polycarbonate greenhouse, since sulfur smoke, firstly, will not damage the surfaces of the greenhouse, and secondly, it will remain on it for a long time in the form of sulfur deposited on each ceiling, ceiling, walls with a layer of literally several molecules thick.

This is enough to expel rodents, to perform disinfection and disinfection.

In order for PESHKI-S smoke to show its maximum efficiency, the room must be sealed as much as possible, and ventilation should be closed. The work procedure requires that during processing inside there were no strangers.

Each time, you should wait for the start of thick smoke with a characteristic odor, which takes up to 20 seconds. It is recommended to work in a protective suit and gas mask of a protection class "A".

What should I do if the checker caught fire?

The probability of ignition of the aerosol forming composition is low. But it is better to keep a piece of thick cardboard and a container of water with you. So that in case of fire, immediately cover the neck of the checkerboard with cardboard or fill it with water. Such a checker is no longer suitable for use.

Since sulfur checkers are sold in whole boxes - knowing the cubic capacity of the room, it will not be difficult to calculate their optimal amount. Upon completion of the treatment, before the personnel access, the room is ventilated for at least 2 hours.

Sulfur Checker - for polycarbonate greenhouses

It is recommended to carry out processing in the spring: the polycarbonate greenhouse is, in fact, a greenhouse. Creating comfortable conditions for plants, you automatically create a favorable environment for the development of mold and fungus that love moisture. Similar "lovers" include bacteria for which sulfuric smoke is harmful.

The PESHKA-S checker aerosol is effective in cases where many crops are grown in the greenhouse, each of which has its own type of disease and pest. In this case, fumigation, as a universal remedy, is most preferable.

Before processing, collect plant debris, inspect them. What is in doubt is better to burn; put the rest in a compost hole.

Thus, you open the soil of the greenhouse for processing. By the way, the effect of sulfuric smoke on the soil is twofold: it is not only protection from pests, but also enrichment of the soil. Then it is necessary to caulk all the cracks and close the vents.

It is necessary to use the agent at the rate of about 1 checker weighing 500 g per 150-250 cubic meters, but it depends on the degree of pest damage (for example, for a spider mite, the concentration must be increased by 2-3 times). The instructions describe in detail how to use the PESHA-S.

When and How to Use Sulfur Checkers to Disinfect Greenhouses

If you are growing plants indoors, one of the common problems could be infection with fungi, bacteria, or insects.

Since greenhouse conditions are good not only for fruits and vegetables, but also for pests, you need to diagnose the problem in time and take measures to eliminate it. One of the most popular disinfection methods is fumigation. Find out what a sulfur block for a greenhouse is, how to choose the right one and how to handle the room correctly.

Choose a tool that is suitable for controlling precisely those pests and diseases that affect your greenhouse.

The benefits and harms of checkers

To determine whether it is possible to use a sulfur block in a polycarbonate greenhouse, it is necessary to objectively evaluate the advantages and disadvantages of such processing. Polycarbonate is not afraid of sulfur gas, but it must not be allowed to act on metal parts and the frame.

The fact is that when mixed with water, the gas turns into caustic acid, harmful to the metal. For this reason, the processing of buildings with metal frames has to be abandoned. Small parts and fasteners protect by processing.

Useful properties include:

- high efficiency;

- fast spread;

- profitability;

- ease of use.

Fumigation - treatment of a greenhouse with smoke. It has a detrimental effect on most types of diseases that plants suffer. Bacterial, viral, fungal diseases, as well as insects and animal pests living in the greenhouse are exposed to toxic gases.

In the process of smoldering checkers, a large amount of smoke is released, which penetrates into all the smallest openings, cracks and inaccessible places. You can’t hide from it in the upper layers of the soil.

At the price, smoke bombs are much cheaper than similar disinfectants in a different form. The use of sulfuric checkers in a greenhouse is a method that can be described as follows: cheap and cheerful. Using these drugs is much easier and less labor intensive than others.

The main drawback, especially relevant for owners of polycarbonate greenhouses, is the oxidation of the metal under the influence of smoke from sulfur drafts. Since the frame is most often metal, ignorance of the rules of operation can seriously damage the structure.

In addition, the sulfur checker has disadvantages:

- mold deep in a tree or soil can survive fumigation;

- dangerous not only for pests and diseases, but also for all other plants;

- toxic to humans.

Since all organics die from the smoke of sulfuric drafts, it is unacceptable to use it in a room where plants have already been planted. For a person, couples are just as dangerous, so it is vitally important not to neglect personal protective equipment during work.

Kinds

"Smoke" can be made from different components. Depending on the composition and the main active substance, these types are distinguished:

- sulfuric;

- didecyldimethylammonium bromide;

- hexachlorane;

- permethrin;

- tobacco.

Each variety has a number of features and is applicable for the control of certain types of pests. For example, sulfuric checkers for disinfecting greenhouses have the widest spectrum of action and do an excellent job with bacterial rot, fungi and mold.

If the composition of smoke bombs for disinfection of greenhouses includes didecyldimethylammonium bromide, they can be used to rehabilitate a greenhouse infected with bacteria or fungi (phomosis, fusarium and other plant diseases).

It is a relatively safe chemical. Didecyldimethylammonium bromide is added even by household products to prevent mold.

Hexachlorane fumigation is used when plants are affected by pests such as aphids, hawthorns, and scoops. The drug fights poorly against bacteria and fungi.

It is also ineffective in combating spider mites. Another universal tool for fumigation of the greenhouse is permethrin. Processing with this substance kills almost all types of insects, as well as their larvae, pupae and eggs.

Small rodents and moles are also afraid of toxic smoke. They do not die, but do not return to the greenhouse.

When burning, tobacco produces nicotine. For plants, it is completely safe, which can not be said about most insects, arachnids and slugs. Fighting with rot or mushrooms with nicotine is a waste of time.

He will not cope with insect larvae. For greater efficiency, it is recommended that smoke be re-treated after 15 days, when the surviving larvae turn into adults.

The fumigation process does not take much time, but there are several nuances that are worth considering.

When to disinfect

Fumigation of the greenhouse with a sulfur checker should be carried out when the crop is harvested, and new plants have not yet been planted. Since smoke is toxic to cultivated plants, no processing is allowed during the growing season.If disinfection is necessary during plant growth, other types of drugs, such as tobacco, are used.

Depending on how strong the infection was, choose a scheme for further processing. If we are talking about a relatively low degree of damage by bacteria or fungi, fumigation of the greenhouse from polycarbonate with a sulfur block is performed once in the autumn.

Disinfection is carried out before preservation of the greenhouse and before planting new seedlings.

There are critical situations when the degree of infection is so high that a single fumigation may not be enough. Then they act according to a different scheme. The room is fumigated in the fall before conservation of the greenhouse.

In the spring, before the planting of new planting material, a control preventive disinfection is performed. In this case, all organisms that accidentally survived after the first treatment and winter frosts will die.

It is recommended to treat the room with smoke in the spring when the earth warms up to 10 degrees. Spring disinfection should be carried out immediately before planting a new seedling. It must be borne in mind that after fumigation, the substance acts for 7-14 days.

How to take care of safety

The use of sulfur checkers for greenhouses is allowed only subject to safety precautions. First of all, we are talking about personal protective equipment.

Toxic sulfur dioxide can cause serious poisoning by inhalation. Even a small amount of gas causes a cough, sore throat, asthma attacks. More serious concentrations threaten pulmonary edema.

To protect the respiratory system during fumigation of greenhouses made of polycarbonate and glass, a gas mask or respirator is used. The mucous membranes of the eyes must be closed with protective glasses. Use clothes with long sleeves, cover all open areas of the body.

When interacting with water, sulfur dioxide turns into aggressive and corrosive sulfuric acid. It is important to prevent its subsidence on the skin. Wear gloves, a hat, and collect hair.

To make the fumigation process safe, checkers are equipped with a wick. After igniting the wick, you have time (about 2 minutes) to leave the room and plug the cracks.

How to properly handle the greenhouse

To process a polycarbonate greenhouse using a sulfur checker, there are several prerequisites:

- the construction is as tight as possible;

- general cleaning performed;

- correctly calculated the required number of checkers.

If the smoke from the burning of the sulfur checker leaves the greenhouse from slots and openings in the coating, this will not only reduce the effectiveness of disinfection, but will also pollute the entire surrounding area with toxic substances.

It is important to make the greenhouse airtight. To do this, close the windows and transoms, if any, tighten the gaps in the doorway, hammer all the cracks at the junction of the polycarbonate with foam, felt or go through a sealant.

General cleaning involves complete cleaning of the topsoil, cleaning of shelves and washing of the coating. All waste of plant origin is taken outside the building.

Instructions for drugs "FAS" and "Climate"

When the room is prepared, the next question arises: how many sulfur drafts are needed to process the greenhouse. The calculation is based on the internal volume of the greenhouse. It matters not only the length and width of the structure, but also its height. The degree of infection is also taken into account. The higher it is, the more money will be needed.

The most reasonable way is to familiarize yourself with the instructions, in which there are manufacturer's recommendations regarding the number of pieces. On average, take 30-60 g of substance per cubic meter. For example:

- FAS - 60 g / m3;

- “Climate” - 30 g / m3;

- tobacco "Hephaestus" - 10 g / m3;

- bulk "Whist" - 1 g / m3.

Different forms of release

Some manufacturers produce smoke bombs in the form of tablets. Depending on the volume of the room, use the right amount of tablets. Other species are released in whole forms. If there is a lot of one package for the greenhouse, it can be cut into pieces.

Polycarbonate greenhouse fumigation

When the preparatory stages in the form of sealing the joints of the polycarbonate and complete cleaning of the room are completed, they proceed to the most important thing - directly disinfection. Processing with the drug "FAS" is carried out in a certain order:

- Protect the metal parts of the polycarbonate greenhouse frame with a protective compound. It can be any grease, for example, solid oil. The main thing is to prevent moisture condensation on the metal surface and the precipitation of sulfuric acid.

- Moisten remaining surfaces with water. Moisten the soil and the walls of the greenhouse. For them, sulfuric acid is not dangerous, and its disinfecting effect will protect against infection.

- Prepare a stand for the drug. For reasons of fire safety, this should be something non-combustible: metal, bricks, concrete block. It will be better if the base is much larger than the checker itself. This will prevent a fire even if the smoke is falling.

- Arrange the desired number of “charges” on coasters at different points in the greenhouse.

- Wear personal protective equipment.

- Set fire to the wick. If there is no wick, kerosene (in no case gasoline) or pieces of paper, newspapers are used for ignition.

- Make sure that the product has started to smolder. Characteristic signs of successful ignition: the appearance of a dark spot on the surface of the drug, the release of caustic smoke and odor.

- Leave the room as soon as possible. Close all cracks, seal the greenhouse.

- When the smoke stops emitting (after 1.5-3 hours), leave the greenhouse smoky for a day for complete disinfection and penetration of the substance into all cracks.

- In a day, open all windows and doors and ventilate the room for at least 48 hours.

On this, the treatment of the smoke bomb for the greenhouse can be considered completed. The room is ready for wintering. In spring, the process should be repeated.

Not always the instruction on the packaging fully discloses how to use sulfur drafts in polycarbonate structures correctly.

Disinfection of the greenhouse is the most important stage of preparation for planting new seedlings in the spring and conservation of the greenhouse in the autumn. Smoke treatment allows you to quickly, efficiently and at no particular cost to get rid of most insect pests, masks, bacteria and viruses that can seriously damage the crop.

Sulfur checker: principle of operation and rules of fumigation

When farm buildings need to be protected from insects, mold and rot, a proven tool comes to mind - a sulfur block, today it is used much more often for a polycarbonate greenhouse. Polycarbonate constructions are recognized as one of the best for growing heat-loving vegetable crops.

In greenhouse conditions, it is advisable to immediately combat all pests using the proven fumigation method. For such disinfection, a smoke bomb is most often used. For periodic maintenance of large greenhouse rooms, this is the best tool.

Smoke from a sulfuric bomb penetrates into inaccessible places where manual spraying is problematic. With this treatment, almost all types of insect pests are destroyed. But it should be remembered that, destroying adult insects, smoke can not hit the eggs of many of them. Therefore, it is necessary to carry out disinfection several times, if its purpose is to destroy insects.

Greenhouse constructions need not only timely processing, but also an irrigation system, it must be taken care of before planting seedlings. The simplest and cheapest option is drip watering from bottles. Such an economical irrigation system will provide plants with the necessary moisture even on hot days.

Types of drafts and the principle of their action

For a summer residence are applicable:

- Sulfur Checker is an excellent tool for processing polycarbonate greenhouses. When it burns, sulfuric anhydride is formed. It is applicable for greenhouses, processing cellars, use it on livestock farms as a means to combat ticks and fleas.

- A checker with hexalchloride is a means for controlling insects in open spaces. It is toxic, destroys even pests that live in the soil.

- Checker with didecyldimethylammonium bromide - for the disinfection of vegetable stores, cellars and basements from mold and fungal infections.

- Checker with permethrin - a means to combat harmful insects. Permethrin has a neuroparalytic effect, it allows you to process rooms of a large area: vegetable stores, warehouses.

According to the principle of action, smoke bombs are divided into 2 groups:

- Group 1 - wick, triggered after ignition of the wick;

- Group 2 - a bomb emitting smoke in contact with water. The kit usually comes with a water tank. A checker descends into it, smoke is released some time after immersion.

The checker does not burn, it either smolders or emits a dense column of caustic smoke.

Sulfuric checkers for the processing of polycarbonate greenhouses from pests:

- "Climate" is conveniently placed in the greenhouse, they help to destroy various types of mold, harmful insects, such as scabies mites, lice, fleas.

- “Fas” - for fumigation of greenhouses, cellars, they destroy not only fungal manifestations and harmful insects, but also rats and mice.

- "Pawn-S" - for the treatment of utility rooms and greenhouses from pests, mold and rot. If you also need to disinfect the soil, it is recommended to loosen the soil.

Fumigation is recommended in the fall or spring. It is convenient to organize work after harvesting. If it was not possible to carry out fumigation in the autumn period, then in spring it is better to take up work when the soil has warmed up.

At a minimum positive temperature, the earth absorbs sulfuric acid better, so the optimal time for processing is the temperature of the soil at + 10 ° C.

After spring fumigation in the greenhouse, it is recommended to shed the soil with liquid vermicompost or phytosporin (200 g per 400 ml of water) to restore the necessary microflora.

Phytosporin is a harmless microbiological preparation that contains spores of beneficial bacteria that protect plantings from many pathogens. It is advisable to use the drug at an air temperature of at least + 15 ° C.

Precautions: A gauze dressing to protect the respiratory tract is not suitable, since the smoke is very toxic. A person who has inhaled a certain amount of smoke will certainly feel nausea, dizziness, severe headache. A respirator must be used to protect the respiratory system.

It is necessary to protect the eyes with special glasses, and hands with gloves.

Instructions for use

Before disinfection, flowers and vegetables must be removed from the premises. Smoke is very toxic; it can destroy both seedlings and crops.

Smoke penetrates everywhere and everywhere, so before processing it is necessary to make sure that it remains inside the greenhouse and does not leak out.

Before using the product, it is important to make sure that there are no open windows, doors and gaps in which smoke can escape. Everything must be closed, the gaps to be caulked. The tool intended for processing is required to be installed in the center of the room on a metal sheet or any other non-combustible surface.

If the space is too large, you need to install several checkers, each in a specific sector. Information about the mass and range should be indicated in the instructions.

If it is necessary to light several checkers, then it is necessary to set fire, starting from the farthest, thus moving towards the exit. The wick is long enough to set fire several checkers and leave the room, carefully closing it behind you. It is necessary to ensure that no one enters the room.

Depending on their purpose and size, fumigators operate from one to 3 hours. After this time, the room must be kept closed for at least 6 hours, after which it can be opened and ventilated for a day or two. It is possible to lay products for storage in processed cellars in 5-7 days.

If necessary, you can carry out several treatments to forget about insects and mold in a greenhouse, shed or cellar for a long time.

leave a comment